How Air Purification Works in Commercial Kitchens

Why a Hydrofilter Is Essential for Indoor Grills and Charcoal Ovens

In theory, a restaurant can operate without a hydrofilter.

Food can be prepared using standard equipment such as combi steamers or conventional electric and gas cookers, which were widely used throughout the twentieth century.

However, this approach significantly limits culinary possibilities. Modern restaurant menus increasingly rely on techniques that involve open flames, charcoal, or wood firing — methods that deliver distinctive flavours and aromas impossible to achieve otherwise.

The Return of Fire-Based Cooking

Over the past decade, professional kitchens have seen a strong revival of traditional cooking methods. The following types of equipment have become especially common:

- Charcoal grills

- Josper ovens (charcoal and wood-fired ovens from Spain)

- Wood-fired grills

- Argentine-style grills

- Wood-fired and Pompeian pizza ovens

- Tandoor ovens

Many national cuisines are returning to their culinary origins, rediscovering techniques that have been used for centuries. Cooking over fire is deeply rooted in human history, and the characteristic aroma of food prepared this way appeals to instinctive senses and memories. This is one of the main reasons why restaurants featuring grill or Josper menus remain so popular.

The Safety Challenge of Open Flames Indoors

Despite their popularity, open-flame cooking appliances present a serious challenge when installed indoors. Simply placing a ventilation hood above a grill or charcoal oven is not only insufficient — it is dangerous.

Connecting such equipment directly to a standard ventilation system creates a significant fire risk. For this reason, installing open-flame appliances indoors without additional protection is prohibited by safety regulations.

The only safe and technically correct way to integrate grills, Josper ovens, or wood- and charcoal-fired ovens into a restaurant ventilation system is by using a hydrofilter.

Why Standard Ventilation Is Not Enough

Without ventilation, smoke and soot would quickly fill the kitchen, settling on ceilings and walls. This problem is obvious and immediately noticeable.

What is less obvious — and far more dangerous — is what happens when smoke-laden air is extracted directly into ventilation ducts without filtration.

Over time, grease, soot, and carbon particles accumulate on the inner surfaces of the ducts. These deposits build up gradually, forming a highly flammable layer. Once it reaches a critical thickness, even a small spark can ignite it, causing a fire that spreads rapidly through the ventilation system and beyond.

Daily cleaning of ventilation ducts is practically impossible, and sparks are inevitably drawn into the system during the operation of grills and charcoal ovens. As a result, the risk steadily increases with each day of operation.

According to industry statistics, the vast majority of restaurant fires are linked to open-flame equipment operating without a hydrofilter.

How a Hydrofilter Works

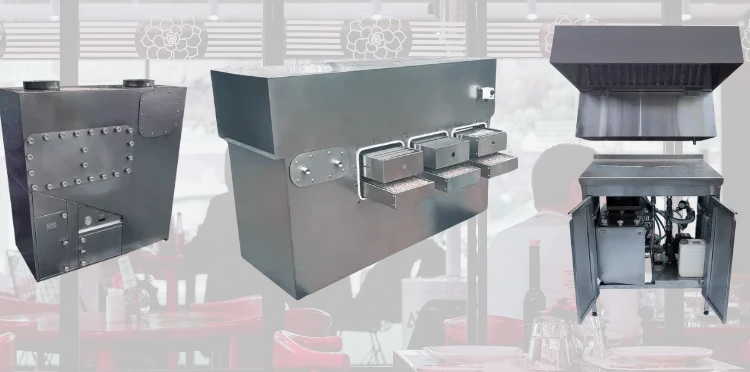

A hydrofilter is designed to clean exhaust air before it enters the ventilation system.

As hot air passes through the unit, smoke, grease, and soot are captured by a specialised filtration system. These contaminants are removed from the airflow, allowing only cooled and purified air to continue into the ventilation ducts. This keeps the ductwork clean and significantly reduces fire risk.

In addition to filtration, hydrofilters use continuous water circulation. Fine water droplets extinguish sparks instantly, preventing them from travelling further into the system.

Many modern hydrofilters are equipped with an automatic washing function. Periodic cleaning removes accumulated contaminants from internal components, helping to maintain stable performance and prevent clogging of spray nozzles and pipes.

While the water-based system continues to provide protection even if cleaning is delayed, regular maintenance is essential to ensure long-term reliability and efficiency.

What Influences the Cost of a Hydrofilter

Several factors determine the final price of a hydrofilter for commercial kitchens.

Materials

High-quality hydrofilters are manufactured from stainless steel, which offers resistance to heat, moisture, and chemical cleaning agents. Painted steel constructions are far less durable, as coatings deteriorate quickly under harsh operating conditions.

Components exposed to fire, steam, water, and detergents — including pipes and nozzles — should also be made from corrosion-resistant materials such as stainless steel and brass.

Level of Automation

Fully automated models are more expensive than manual versions. Automation simplifies operation, reduces staff involvement, and optimises water consumption, which is particularly important in urban environments with metered water supply.

Custom Configuration

Restaurants with limited space or unconventional ventilation layouts may require customised solutions. Tailored designs often involve additional engineering work, which can increase production costs.

Components and Supply Chain

Some elements may be sourced from international suppliers, meaning that pricing can be influenced by currency exchange rates and market conditions.

Hydrofilters play a critical role in ensuring fire safety and air cleanliness in modern restaurant kitchens that rely on open-flame cooking. They allow chefs to use traditional and expressive cooking methods while maintaining compliance with safety standards and protecting both property and people.

Properly selected, installed, and maintained hydrofilters are not an optional accessory — they are a fundamental component of any indoor grill or charcoal oven installation.